Our facilities enable us to accommodate the largest blocks and machine them to tight tolerances.

- Surface Grinding and cutting facilities

- Pre-assembly allowing full customer inspection

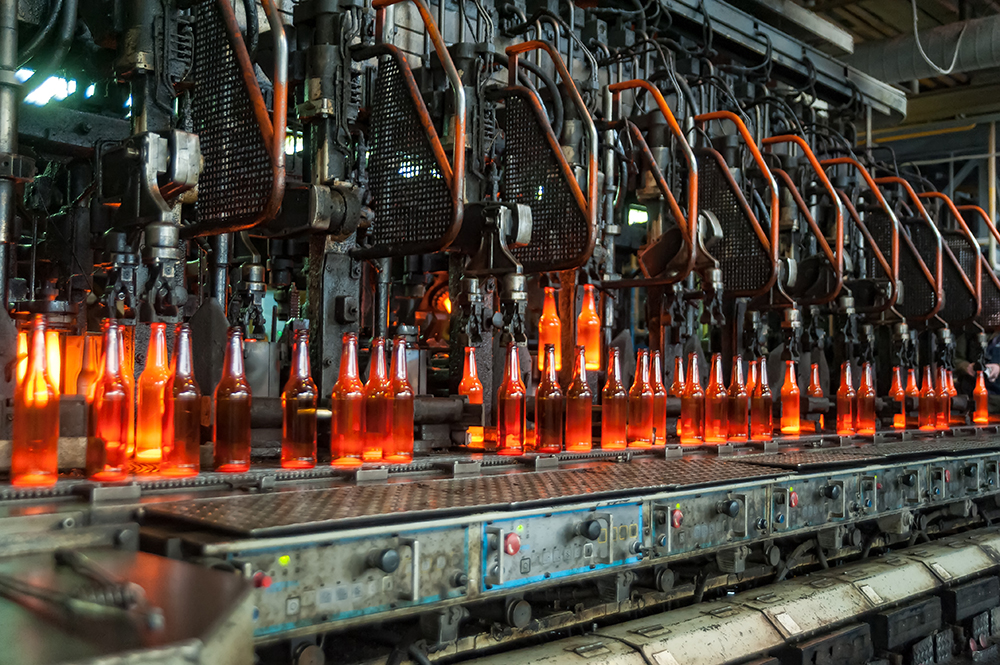

Magma Ceramics specialises in the manufacture of precision cast refractories for the float glass industry.

- Our products include Roof Tiles, Hanger Bricks and Entrance / Exit Lintel blocks (Lip Tiles or Sill Blocks)

- Magma Ceramics can also provide Zircon Patch for hot patch repairs of furnace superstructure

Magma Ceramics is a leading supplier of Glass Melting Crucibles to the Art and Studio Glass Sector. With a vast range of standard sizes and designs and many years of experience, Magma Ceramics offers reliable products to suit your needs.

With manufacturing facilities in both UK and Vietnam, Magma Ceramics is well positioned to supply high quality refractory parts to these global markets whilst remaining competitive on price.

Materials include Sillimanite, Mullite and Zirconia-Mullite providing superior performance for all glass applications.