The production of methanol is a two-stage process. The first stage is the conversion for feedstock to synthesis gas. Typically, the feed is purified to remove compounds that can affect the downstream catalysts and plant. The feed is then mixed with steam and reformed over the steam reforming catalyst according to the following reactions:

Steam Reforming

CH4 + 2H20 ↔ 4H2 + CO2

Water Gas Shift

CO + H2O ↔ H2 + CO2

Oxygen may also be used to improve conversion by burning part of the process stream according to the following reactions:

Combustion

2CH4 + 4O2 ↔ 2CO2 +4H2O

2CO + O2 ↔ 2CO2

2H2 + O2 ↔ 2H2O

This produces a syngas rich in carbon oxides and hydrogen. The syngas is then purified to remove water and impurities before being fed forward to the second stage.

The second stage of the methanol process is usually called the synthesis loop. The heart of the loop is a partial conversion reactor where the synthesis gas reacts to form methanol according to the following reactions:

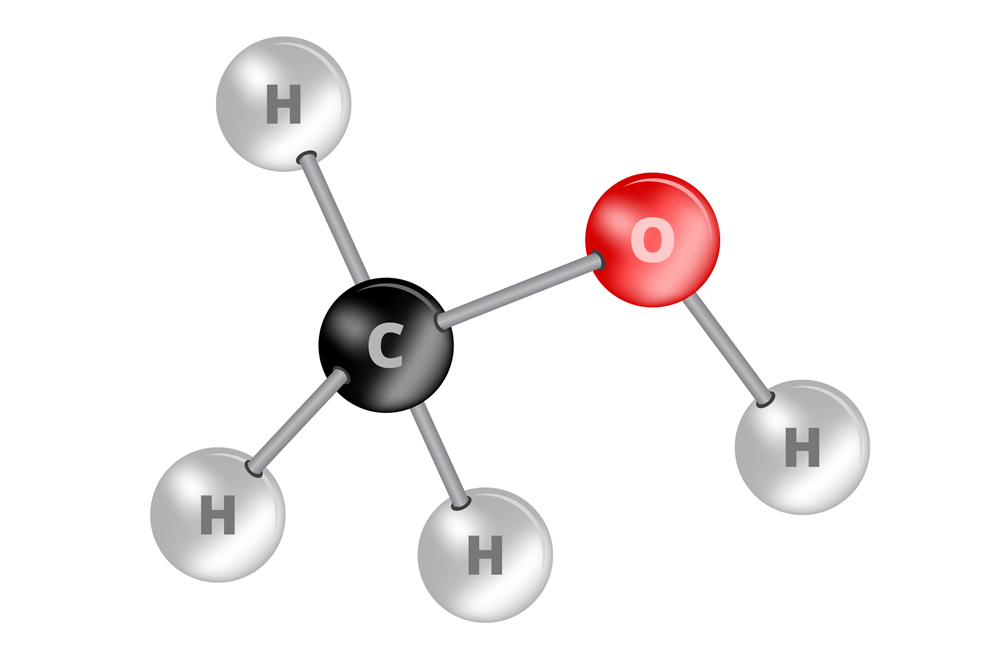

CO + 2H2 ↔ CH3OH

CO2 + 3H2 ↔ CH3OH + H2O