Magcat Textured® Catalyst Technology

Our Magcat steam reforming catalysts are designed to improve heat transfer coefficient, provide high intrinsic strength and lower pressure drop across the process. These properties deliver performance benefits at constant plant rate including lower pressure drop; lower tube skin temperatures; and reduced reforming firing. This gives an overall increase in operation efficiency at the given operating conditions.

Traditionally steam reforming catalysts form the catalyst support from tabletting/pelleting alongside high temperature firing to stabilise the structure. This technique gives a smooth external surface.

At Magma we have developed our forming process based on ceramic technology. With over 40 years of experience in the Ceramics Industry, we have adapted this technology for catalyst application to control the ceramic polymer matrix and porosity of our products. This technique allows us to form complex shapes which further increase the voidage and geometric surface area. It is also through this technique we have developed a catalyst with surface texturing on the outside of the particle.

Our textured catalysts create a more turbulent gas flow around the catalyst and therefore disrupts the thin static gas layer at the inside of the tube wall. This results in a higher heat transfer coefficient (HTC), reduced tube skin temperature and accelerated mass transfer of reactants to the active catalyst site.

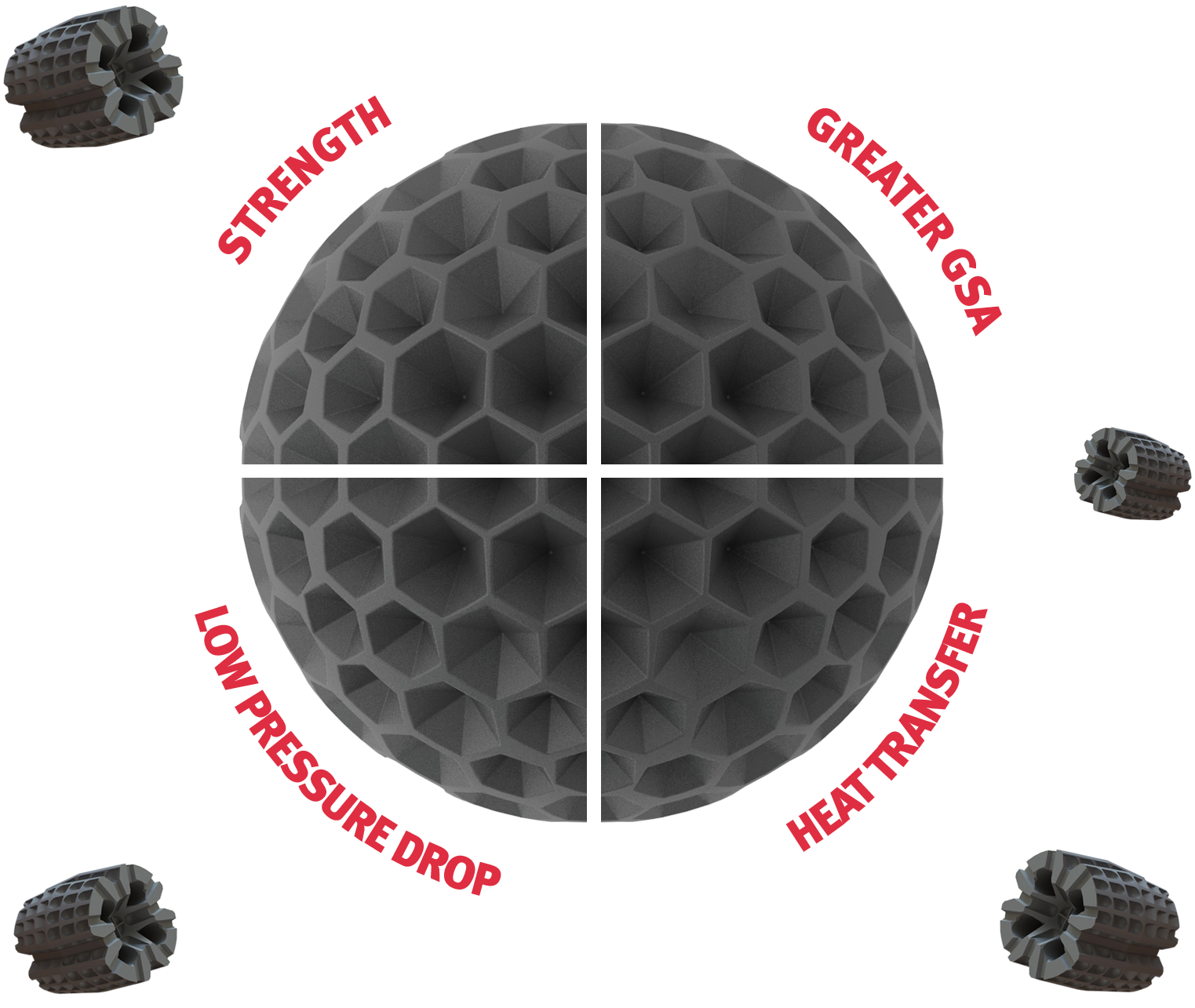

The Advantages of Magcat Textured®

STRENGTH

- Magcat > 300 lb/ft (+50% higher than competitor*)

- Higher Attrition Resistance

- Stronger pellets that pack better

* Typical dependant on material type

GREATER GSA

- +30% improvement in active surface area

- More sub-surface area available for chemical reaction

- Optimised Nickel loading and placement avoiding wastage

LOWER PRESSURE DROP

- More methane processed

- Reduction in operating costs

- Greater strength reduces pressure drop increase over life of catalyst

HEAT TRANSFER

- Maximum Heat Transfer

- Uniform packing reduces thermal stress on the reactor tube

- Extending tube life span therefore reducing cost of re-tubing

The Loading of Magcat Textured® Catalyst

MagCat Textured® Spheres pack uniformly with minimal void space, creating an even distribution of gas flowing throughout the tube.

Here's our latest video to demonstrate

these benefits!

Our Products

Featured Articles

Want More Hydrogen?

A top five US refiner uses steam methane reforming (SMR) catalysts to increase hydrogen production.

Gary Bennington, UNICAT & Magma Group, and Tom Ventham, UNICAT & G. W. Aru LLC, discuss the efficacy of this solution in supporting the hydrogen economy, whilst reducing fuel requirements and emissions.

21st Century Hydrogen

Lead Article March 2021 from Hydrocarbon Engineering discussing 21st Century hydrogen and the development of a new steam methane reforming technology.